The case for modular softwall cleanrooms over hardwall installations

An aerospace company needed a contamination-controlled space for the manufacturing and assembly of critical aircraft components. They were presented with a choice – a hardwall or a softwall cleanroom. Their particular application called for extremely stringent contamination and environmental control combined with high static pressure to ensure the integrity of the aircraft components. So the company chose to go with a hardwall cleanroom.

Meanwhile, another company involved in electronics manufacturing also needed a contamination-controlled space to assemble sensitive electronic components. Given tight production deadlines, their priorities were flexibility and rapid deployment while still maintaining an effective barrier against dust and other contaminants. They chose to go for a modular softwall cleanroom.

Cleanroom types: What they are and why they matter

Cleanrooms are an essential part of any industrial application that calls for environmental control. From pharmaceuticals and biotechnology to electronics and defence, cleanrooms are indispensable in research, manufacturing, assembly, and sometimes even storage.

While cleanrooms have applications across industries, every industry and every application has different cleanroom requirements. Depending on your business objectives, your production goals, the nature of your industry and product, and the unique context within which you operate, you will have to choose between traditional stick-built cleanrooms and modular cleanrooms, between hardwall cleanrooms and modular softwall cleanrooms, static cleanrooms and portable cleanrooms.

Each of these construction types comes with its own set of benefits, constraints, costs, and applications. You would choose one depending on your desired performance standards and compliance requirements.

While each type of cleanroom has its place, when it comes to convenience, flexibility, and cost, we always recommend modular softwall cleanrooms – not only do they offer all the contamination control capabilities of any other cleanroom, but they also have added benefits that make them particularly useful if you’re dealing with constraints of time, space, and budget.

So, let’s dive right into our case for modular softwall cleanrooms over hardwall installations. We’ll begin by exploring the features of each type before we compare the two.

Hardwall cleanrooms: The what, why and where of traditionally built or modular cleanrooms with hard walls

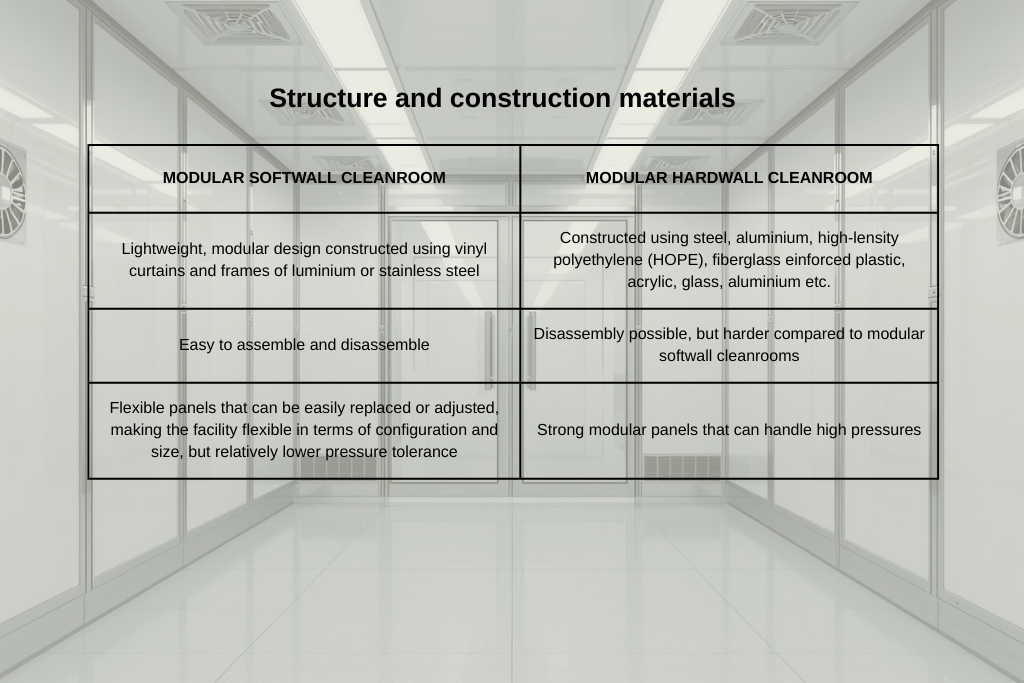

A hardwall cleanroom is a controlled environment made of (you guessed it) hard or rigid walls. Hardwall cleanrooms aren’t always traditionally built; they can also be modular, portable cleanrooms. Regardless, they are characterised by the fact that their walls aren’t flimsy or soft. Traditionally, hardwall cleanrooms are built using steel, aluminium, or polycarbonate, among other materials.

Like all cleanrooms, hardwall cleanrooms are built to create strictly controlled environments (though they may also be used for less stringent applications). Where they stand out from other modular cleanrooms is in their ease of environmental control, suitability for long-term use, and durability against external environmental conditions.

Just like traditionally constructed cleanrooms, hardwall modular cleanrooms have solid walls, but like other modular solutions, they retain a level of flexibility. On the whole, hardwall modular cleanrooms are the perfect balance between stick-built construction and prefabrication.

The benefits of hardwall cleanrooms

Hardwall cleanrooms, whether they are stick-built or modular, offer several benefits:

- Strong environmental control. From particle control and humidity to temperature and static pressure, hardwall cleanrooms offer unparalleled environmental control for whichever ISO standard you want to meet, be it ISO 1 or ISO 9. This level of control is extremely important in any cleanroom.

- Mounted equipment. Modular hardwall cleanrooms can be designed around equipment that is already floor- or ceiling-mounted. This means that modular hardwall setups can also be portable cleanrooms if you so desire.

- HVAC incorporation. Hardwall cleanrooms can use your building’s existing HVAC system to maintain cleanliness standards. Given the rigid walls, modular hardwall cleanrooms can also be fabricated with integrated HVAC and other building systems.

- Durability. Hardwall cleanrooms have a durable frame and strong ceiling grid. This rigid structure ensures that the cleanroom provides a stable and secure environment, doesn’t sag, and stands the test of time while providing good contamination control in the long term.

- Ease of cleaning. Compared to modular softwall cleanrooms, their hardwall counterparts are easier to clean because of their smooth, hard, and non-porous surfaces, which can be quickly and easily sanitised.

- Higher static pressure. The rigidity of the hardwall cleanroom walls makes them capable of withstanding and maintaining higher levels of static pressure, ensuring highly effective particulate intrusion prevention.

Applications of hardwall cleanrooms

Hardwall cleanrooms, whether they are traditionally built or modular cleanrooms, offer a high level of control over the internal environment. They are ideal for large cleanrooms, stringent regulatory classifications, and long-term projects in industries such as pharma, biotech, medical device manufacturing, aerospace manufacturing, electronics, semiconductors, and more.

Softwall cleanrooms: The what, why and where of modular softwall cleanrooms

While not all modular cleanrooms are softwall setups, softwall cleanrooms are always modular installations.

Modular softwall cleanrooms are controlled environments built using lightweight or “soft” materials, as their name suggests. Think flexible curtain walls made using vinyl strips and a metal frame, typically steel or aluminium. Like a tent.

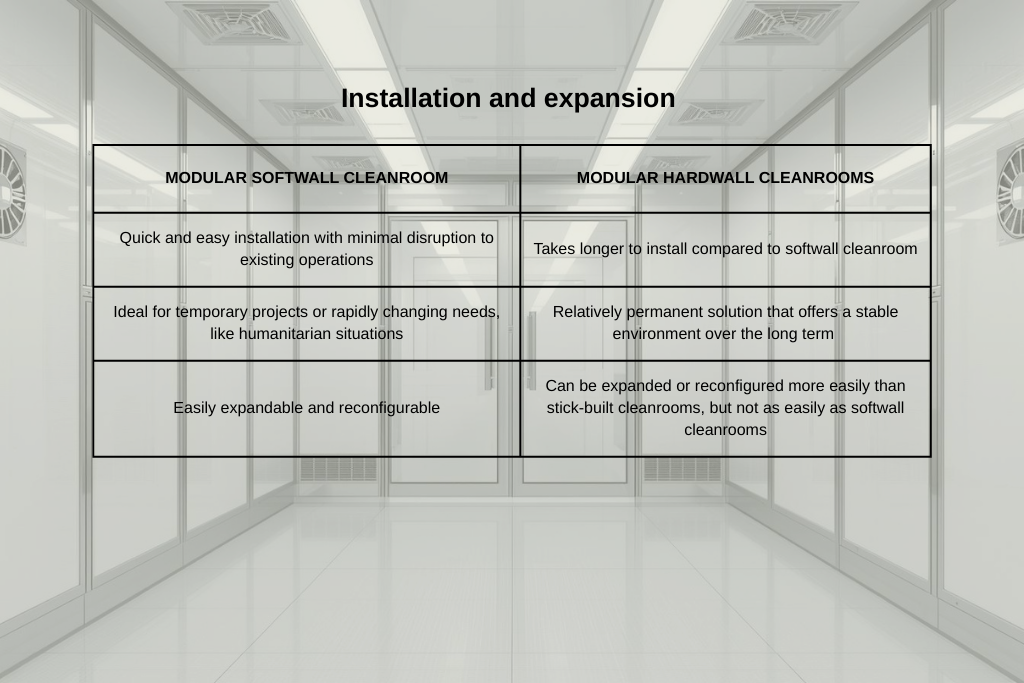

Fairly quick to install, softwall cleanrooms can be freestanding, mounted on wheels, or suspended from an existing structure. Softwall modular cleanrooms can provide a portable cleanroom setup of any size. This makes them suitable for creating controlled environments in myriad situations.

The benefits of modular softwall cleanrooms

The main advantages of modular softwall cleanrooms is that, compared to hardwall setups, they are flexible, easily relocatable, and cheaper. But that is hardly all. Stay tuned for part two of this blog post to know why softwall modular cleanrooms often win out over hardwall cleanrooms – and to know which of these two construction techniques you should opt for.

Softwall modular cleanrooms have several benefits:

- Flexibility. Whether they are freestanding or attached to an existing structure, softwall modular cleanrooms are lightweight and highly flexible. The use of vinyl curtains lends them this flexibility, which makes them easy to set up and incredibly versatile. Whether you want to adjust your setup, move it, replace it, or expand it, softwall modular cleanrooms are an effective solution in terms of cost and convenience. They are portable cleanrooms in the truest sense of the phrase.

- Customisability. Given their flexible build, softwall cleanrooms are highly customizable to your needs. Whether it’s changing door types or fitting in the necessary HEPA or ULPA filters, most adaptations are possible to suit your specific applications.

- Ease of installation/construction. Modular softwall cleanrooms are the fastest to install. Whether you’re setting up a new facility or expanding an existing one, the process requires minimal tools and personnel. This makes modular softwall cleanrooms the perfect option for projects on tight timelines.

- Space-saving. Real estate is a significant investment for any manufacturing or research operation. But since softwall modular cleanrooms are so compact, they can fit in the most unlikely of spaces. Since they are portable cleanrooms, when a project is done, they can be easily relocated. All of these features make investing in a modular softwall cleanroom a space-efficient and cost-saving decision.

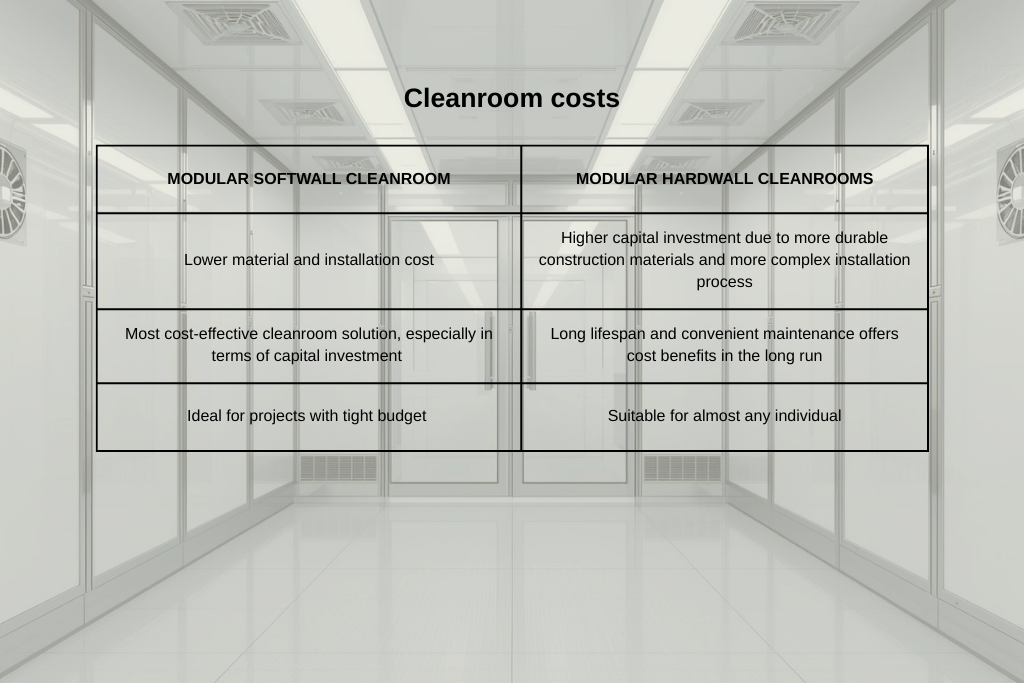

- Affordability. This is key. Cleanrooms are massive investments, and every cost adds up – equipment, personnel, maintenance, air filtration systems, and the like. The construction of modular softwall cleanrooms needs minimal materials – it can also use sustainable and/or recycled materials. The design of softwall modular cleanrooms is also fairly simple and straightforward. Finally, their installation is also very quick, especially when compared to hardwall modular cleanrooms and traditionally constructed cleanrooms – this significantly cuts your construction costs.

Applications of softwall cleanrooms

Since they can contain dust and sound, modular softwall cleanrooms can suit a variety of ISO classifications and industries from electronics and pharma to biotech. These are similar industries to those in which hardwall cleanrooms are used, but softwall cleanrooms are typically used for less stringent applications, like assembly, packaging, storage, and/or early-stage R&D. Mostly, modular softwall cleanrooms are perfect for projects that require rapid deployment and high adaptability.

Naturally, softwall cleanrooms have some drawbacks – they are harder to clean compared to hardwall cleanrooms, have lower static pressure thresholds, and may not be chemical resistant. But their benefits – high flexibility and low cost – usually outweigh the cons in certain applications.

Hardwall vs softwall modular cleanrooms

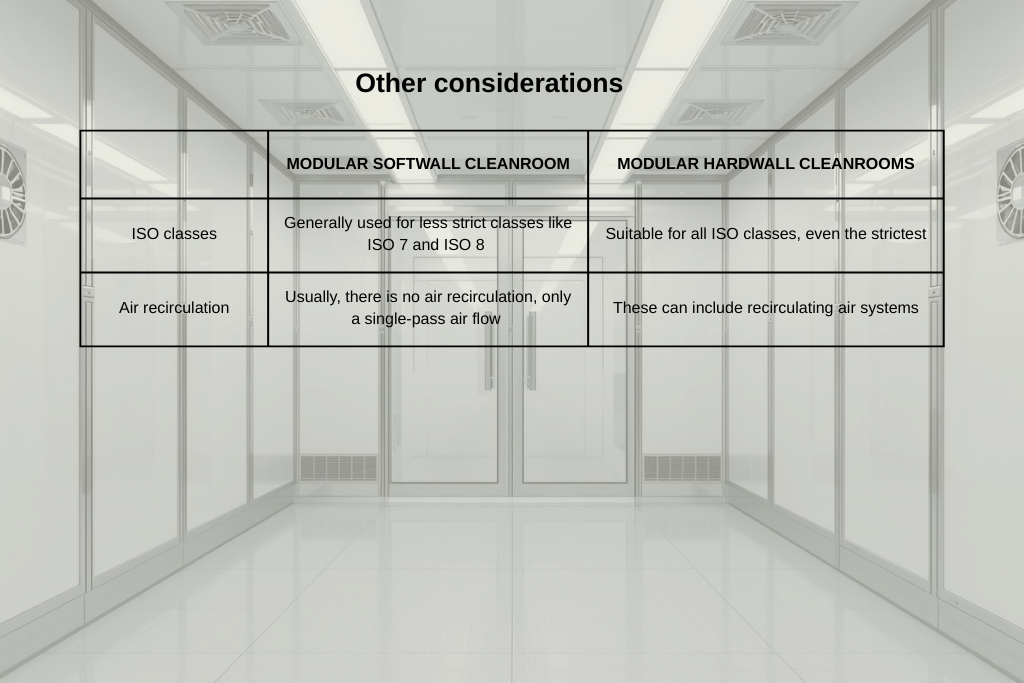

When you’re comparing modular cleanrooms of the two types, there are three factors that you should consider: structure and construction material, installation and expansion, and costs, both capital and operating.

Making a decision: Should you go the hardwall or softwall modular cleanroom route?

You may wonder if it really makes such a difference if you choose one over the other. But in industries that require the strictest contamination control, even the smallest mistake can have massive consequences on the success of your project. Comparatively, the design and construction of your cleanroom are extremely, extremely important.

Choosing the right cleanroom construction type is essential for you to ensure optimal cleanroom performance as well as compliance with regulatory standards. Either over-engineering or under-engineering your cleanroom can have disastrous consequences for your project from a cost or compliance standpoint. So, here’s how you should go about making a decision:

- Industry and application requirements. Assess the specific cleanliness and regulatory standards required by your industry. Assess the specific needs of your project. This includes the level of cleanliness you must maintain, the type of contaminants you must control, and the environmental conditions you must create and sustain. Also consider the budget, timelines, and goals of your project. This will help you choose between the flexibility of modular softwall cleanrooms and the stringent control of modular hardwall cleanrooms.

- Budget. Your budget will place constraints on what type of infrastructure you can invest in. Analyse your budget for both your capital investment and operating costs. While softwall cleanrooms are more affordable upfront, hardwall cleanrooms may offer better long-term value.

- Space constraints. Softwall cleanrooms generally take up less space due to their flexibility with layout. Hardwall cleanrooms call for more space and careful planning and construction.

- Project timeline. If you need a cleanroom solution on a fairly short timeline, softwall cleanrooms are your go-to solution.

- Equipment requirements. The type of equipment you need to use will also determine the construction style of your cleanroom. Hardwall cleanrooms can accommodate heavy machinery while providing better support for HVAC and other building systems. Softwall modular cleanrooms, on the other hand, are better suited to straightforward configurations and lighter equipment.

At the end of the day, the ideal cleanroom solution for you will depend on your particular context in terms of business goals, industry standards, budget, process technology, and beyond. While you should opt for hardwall cleanrooms when you need stricter ISO classifications, long-term durability, or rigid environmental control, you should go the softwall route when you’re dealing with small budgets, short timelines, and when flexibility is key.

If you’re still unsure of which option is best for you, reach out to us, and our team of experts will be happy to guide you through the process.