The complete guide to turnkey cleanroom installation

The worlds of research, services, and manufacturing across industries like the life sciences, electronics, and automotives have become overwhelmingly complex today. Fortunately, infrastructure development in these industries has also evolved to keep up with this complexity. Specifically, in industries that require controlled environments, turnkey cleanrooms have become the go-to solution. Be it biopharma research, semiconductor…

Read MoreClean rooms in the pharmaceutical industry: The complete setup guide

Clean rooms in the pharmaceutical industry are the foundation of safe, compliant, and high-quality drug development and manufacturing. From early-stage research to commercial-scale production, clean environments protect products, processes, and people. They help pharmaceutical companies meet strict regulatory standards while maintaining consistency and efficiency. If you’re in biopharma and are planning a new facility or…

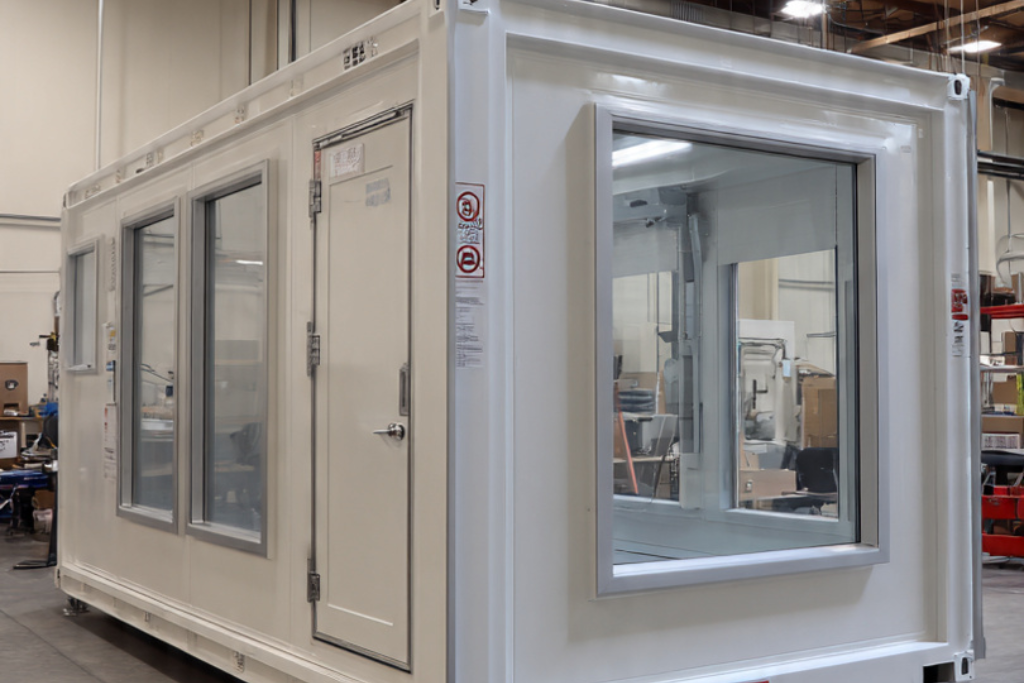

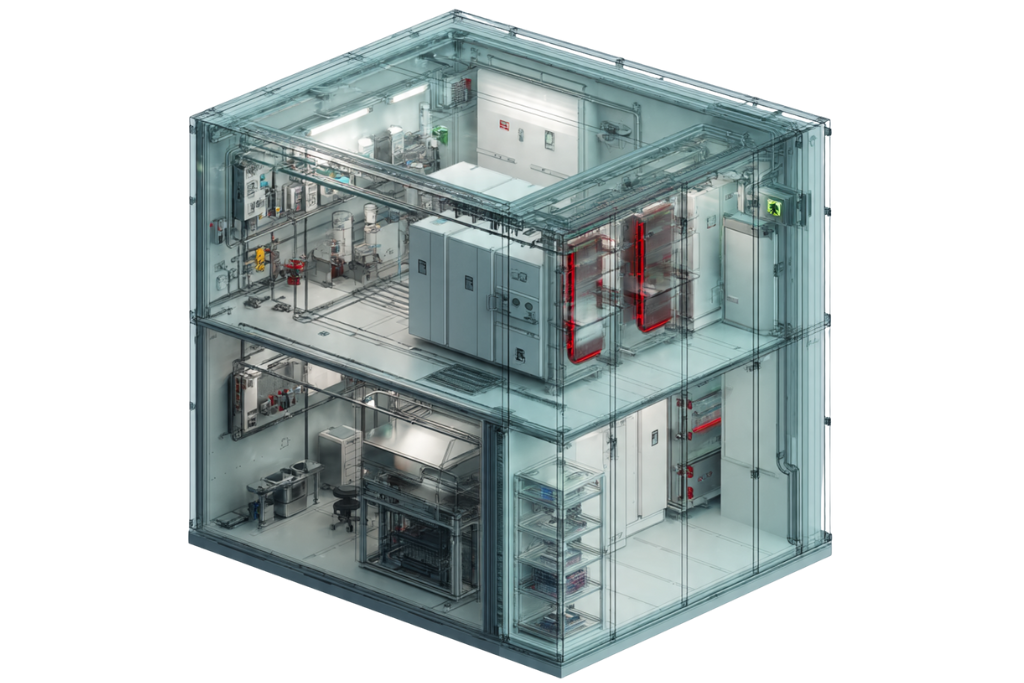

Read MoreA complete guide to building a modular cleanroom

In today’s rapidly evolving manufacturing and research environments, clean and controlled spaces are essential. A modular cleanroom provides an effective solution for industries from pharmaceuticals to electronics and biotechnology. This complete guide will walk you through everything you need to know about building a modular cleanroom. We focus on design, planning, construction and operational considerations.…

Read MoreThe essential guide to choosing the best cleanroom manufacturing companies

No matter what you manufacture, research or operate in a cleanroom, the design and build of your facility will impact the results you get. And how do you ensure that your cleanroom gets not just the best design and engineering in the market, but the best design and engineering for you? Only the best cleanroom…

Read MoreUnderstanding modular clean room costs: A complete breakdown

What drives modular clean room cost and why the numbers can vary. Modular clean rooms have quickly become the preferred choice for organisations that want a controlled, compliant environment without committing to long construction timelines or disruptive on-site builds. They offer flexibility, predictable quality and easier ongoing management compared to traditional stick-built clean rooms. Still,…

Read MoreHow to choose the best BSL 3 labs for your facility

Biosafety isn’t bought. It is earned through good design, strict protocols, and constant vigilance. That’s why the best BSL 3 labs aren’t just chosen from a BSL 3 lab manufacturer. Establishing and maintaining compliance with a biosafety level is an ongoing process rather than a one-and-done event. Through this process, you want not just a…

Read MoreThe complete guide to cleanroom solutions for pharmaceutical manufacturing

Cleanrooms. From stick-built cleanroom systems to modular cleanroom solutions. From hard wall to soft wall cleanroom variants. From dry rooms to clean zones. From ISO standards to Federal Standards in the United States and EU-specific GMP guidelines. There’s a world of concepts, processes, techniques, and standards you must be familiar with before you get yourself…

Read MoreHow to set up a biosafety level 4 laboratory: A step-by-step guide

From the Ebola and Marburg viruses to the Nipah and the Crimean-Congo Haemorrhagic Fever (CCHF) causing ones, many pathogens share a combination of factors. They’re extremely virulent, especially because of their potential for airborne spread. The lack of effective treatments and vaccines makes them notorious for their high mortality rates. They’re among the most lethal…

Read MoreHow to choose the best pre-engineered cleanroom for your data center

If there’s one thing that’s guaranteed in our digital world of today, it’s the robust demand for servers and data centers, especially since the beginning of the generative AI era. The leap has been in terms of not only quantity but also quality. Modern servers have made tremendous leaps in sophistication over the years. Today,…

Read MoreThe case for modular softwall cleanrooms over hardwall installations

An aerospace company needed a contamination-controlled space for the manufacturing and assembly of critical aircraft components. They were presented with a choice – a hardwall or a softwall cleanroom. Their particular application called for extremely stringent contamination and environmental control combined with high static pressure to ensure the integrity of the aircraft components. So the…

Read More